CheckSum Low Cost IC Test Systems

CheckSum test systems are used by the major IC design and assembly companies to test devices such as ICs and sockets for several electrical defects such as opens and shorts, incorrect resistance, capacitance or diode voltage.

The types of devices tested are typically digital ICs with dual, quad, BGA, or Flip Chip CSP (fcCSP) packaging. Since the test system interfaces to the IC with a load board, the system can quickly accommodate virtually almost any device up to 8000, or more, connections.

Rather than rely on TestJet Technology which provides a limited measurement of connectivity, these device test systems use the same test technology and measurements used by the high-performance IC test systems to validate total connectivity.

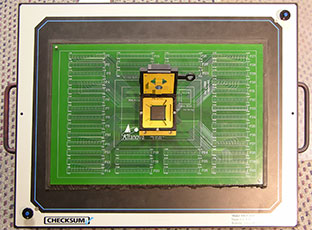

CheckSum Bed of Nails Device Test System Overview

2800 Channel Test Head (load board removed)

The CheckSum test systems are a low-cost production solution for testing even cost-sensitive IC devices. The test system’s small footprint and low power consumption allow these systems to also be used in both lab and cleanroom environments.

The system architecture can be configured with a wide range of channels. Typical configurations support up to 1000 channels, or up to 8000 channels when fully-equipped. The system can be setup to test multiple sites of devices. The high-speed solid-state switching keeps test times low. All test results can be saved for SPC (statistical process control) analysis with the built-in software package. The system login and password protect the test programs from modification by anyone that is not authorized.

The modular architecture scales from desktop test and debug with real-time analysis tools to high-volume, multi-site production on the same test system. The mechanical infrastructure can easily grow to meet your future requirements. The system can be controlled by a handler to automate the change of parts and testing without any operator interaction.

The device test system offers all of this capability with a floor space requirement of less than one meter-square. By contrast, traditional ATE systems require at least four to six times this area to deliver similar capability. The CheckSum system is air-cooled, minimizing HVAC requirements, and uses a standard 115V or 230V outlet.

The system uses a standard Windows PC to control the measurement subsystem. The connection to the DUT (device under test) can be made with a load board or other preferred interface mechanism.

IC Socket Testing

Load board installed with open IC socket, insert and test IC

The test system’s high pin count with very repeatable, low-resistance 4-wire Kelvin tests and auto-learn capability make it ideal for testing IC sockets for opens and connectivity. The system can be interfaced to an automated part insertion handler to automate the insertion and removal of components and testing.

Burn-In Boards

The test system’s high pin count with reliable and repeatable, complex impedance measurements with multiple guard channels plus an auto-learn capability make it ideal for testing all types of boards including burn-in boards. The IC sockets on the burn-in boards require special connections or test type ICs to verify open pins.