Designed to meet the needs of the small/medium batch manufacturer who requires high levels of production flexibility, the Jade MKll entry-level system offers uncompromised selective soldering quality at a very low cost.

The Jade MKII is a hand load system, incorporating a universally adjustable tooling carrier capable of accommodating PCB’s or pallets up to 457 x 508mm.

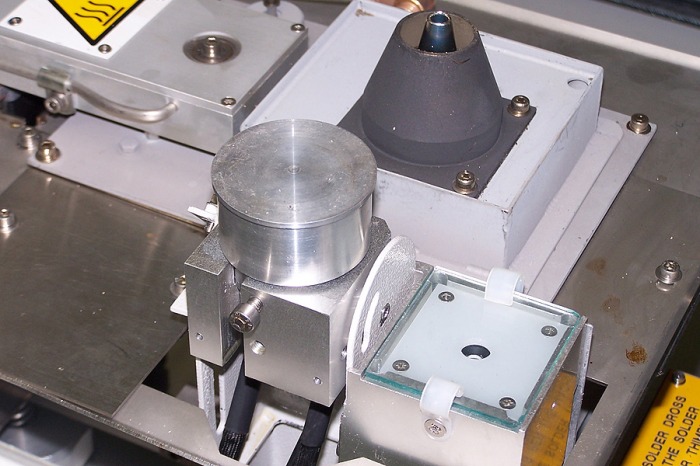

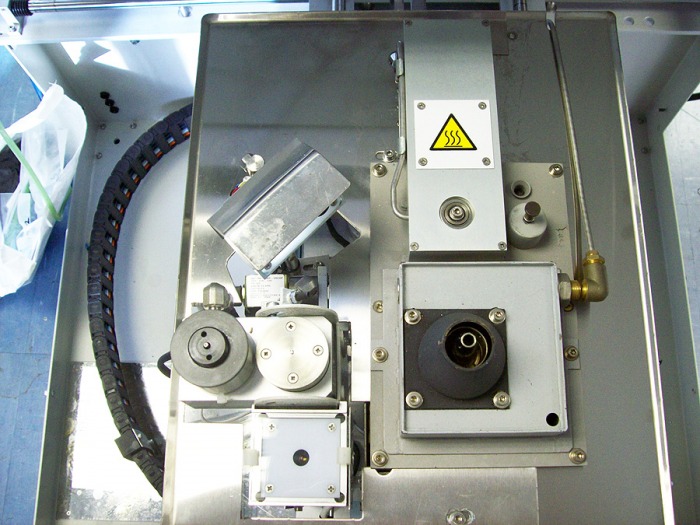

Our patented Drop-Jet design fluxer offers quick and effective flushing of the pressurised flux chamber. This helps to keep maintenance levels to a minimum whilst enabling use of higher solid content fluxes as well as water-soluble fluxes.

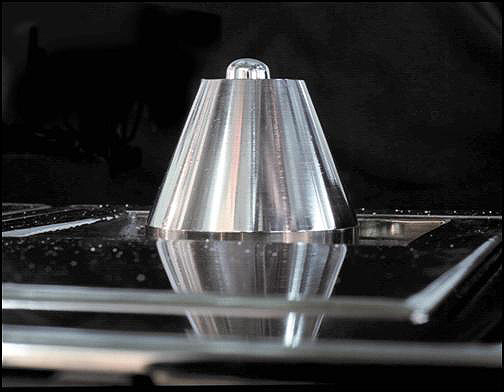

As part of the entry-level philosophy for this system, a low maintenance solder bath and pump mechanism has been developed which moves in three axes of movement whilst not limiting access to the PCB. Solder is applied using proven technology through our AP nozzle design or custom specialised nozzles, incorporating patented spiral solder return to bath technology offering reduced solder balling potential.

As with all Pillarhouse systems, the soldering process is enhanced by a hot Nitrogen curtain which provides an inert atmosphere. This method of soldering also assists in the prevention of oxidisation and provides a local preheat to the joint, thus reducing thermal shock to localised components.

The Jade MKII is controlled by a PC, through PillarCOMM, a Windows® based ‘Point & Click’ interface with PCB image display.

Additionally, our PillarPAD offline package allows the operator to produce programs independently from the machine using Gerber data.

Integral PC and machine mounted TFT monitor

Inerted Nitrogen system

Auto solder top-up (wire feed) & solder level detect

Drop-Jet fluxer

Set of AP style solder nozzle tips

Internal fume extraction

Colour programming camera

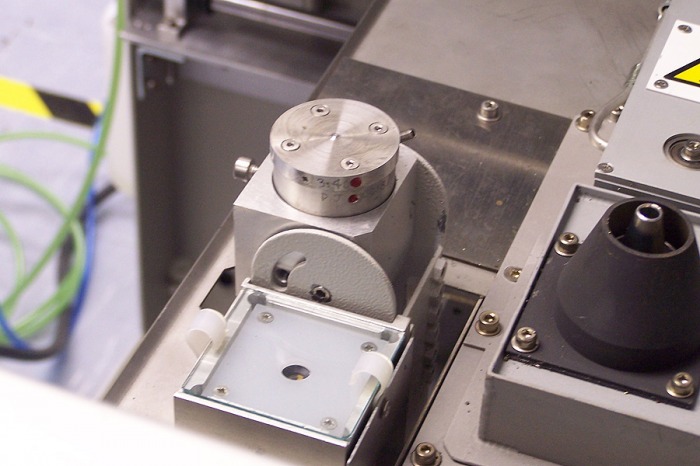

Solder wave height measurement and correction

Universally adjustable tooling carrier

Thermal nozzle calibration system using integrated setting camera (requires manual correction)

PillarCOMM Windows® based ‘Point & Click’ interface

Multiple level password protection

Manual fiducial correction

Lead-free compatible

Day-to-day service kit

Flux presence sensor – thermistor style

Flux spray, flow and spray & flow

Pump rpm

O2 ppm

Nitrogen flow

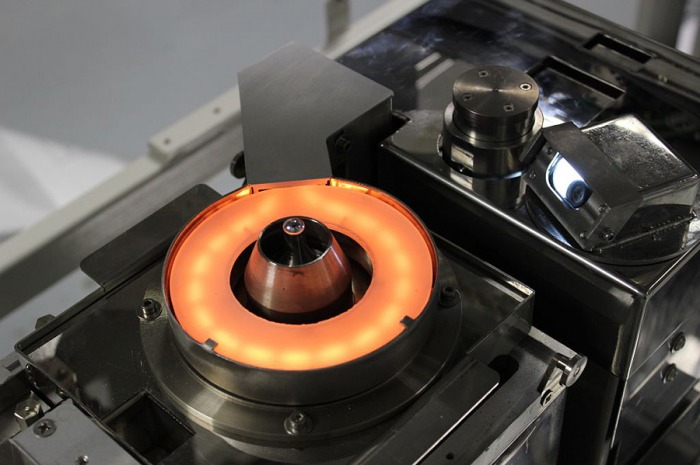

Top-side instant IR preheat

Closed loop temperature control – via pyrometer or thermocouple

Bottom-side IR ring heater

Bottom-side hot Nitrogen selective preheat

Automatic fiducial correction

Ultrasonic fluxing

Dual Drop-Jet / ultrasonic fluxing

Laser PCB warp correction

Micro nozzle assembly

Solder reel identification

Rapid change solder bath and pump system capability – does not include solder bath and pump

Solder bath coding – identifies correct bath for program – only suitable for use with rapid change solder bath and pump system

Encoders on X, Y and Z axis

Larger PCB handling size

Nitrogen generator

Height: 1403mm / 55” – excluding light stack

Width: 1000mm / 40“

Depth: 1351mm / 53”

Board size: 457mm x 508mm / 18”x 20” (larger PCB size available upon request)

Edge clearance: Above / below 3mm

Height clearance: Above / below 40mm nominal

Above 190mm – special application

Solder: Most commonly used solder types – including lead-free

Solder pot capacity: 8kg

Applicators: AP style – 2.5mm to 16mm dia.

Extended AP style – 2.5mm to 20mm dia.

Micro nozzle – 1.5mm to 2.5mm

Jet-Tip style – 6mm to 20mm dia.

Jet-Wave nozzle – up to 25mm width

Special dedicated nozzles available upon request

Flux: Low maintenance Drop-Jet system. Low solids (below 8%), no clean flux, pressurised and inerted system, optional water soluble system available

X, Y & Z Axis resolution: 0.1mm

Repeatability: +/- 0.05mm

Nitrogen usage: 35 litres gas/min. 5 bar pressure

Nitrogen purity: 99.995% or better

Air supply pressure: 5 bar / 72 psi

Power supplies: Single phase + PE

Voltage: 208V – 250V

Frequency: 50/60Hz

Power : 4kVA

Power with IR preheat: 6.5kVA – Top-side

8kVA – Top with bottom-side ring heater

Transport: Hand load

Tooling: Integral adjustable board guides, includes finger extensions and board clamps

Programming: PillarCOMM Windows® based ‘Point & Click’ interface