Jade Prodex

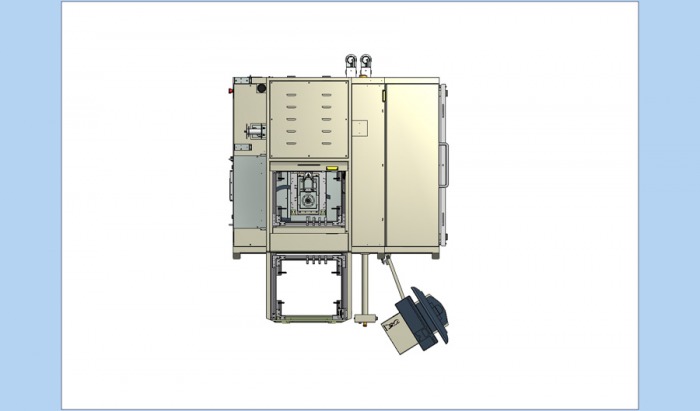

Ultra-flexible, offline, multi-platform quick load twin PCB rotary table selective soldering system

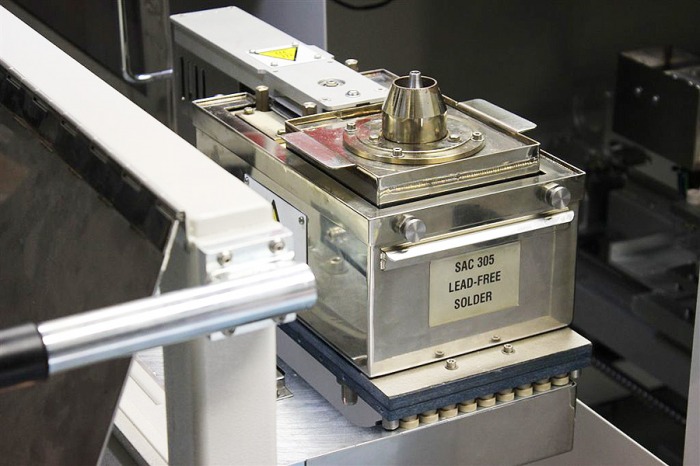

Designed to meet the needs of the small batch manufacturer who requires high levels of production flexibility. The Jade Prodex offers the ability to regularly change solder alloys without incurring expensive down time, whilst the solder bath cools down and heats up during a regular manual changeover process.

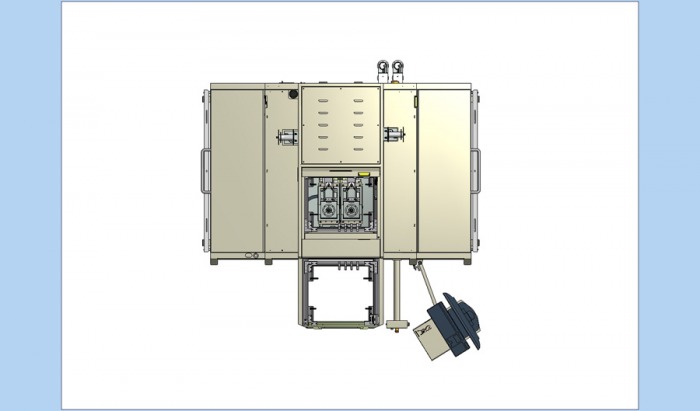

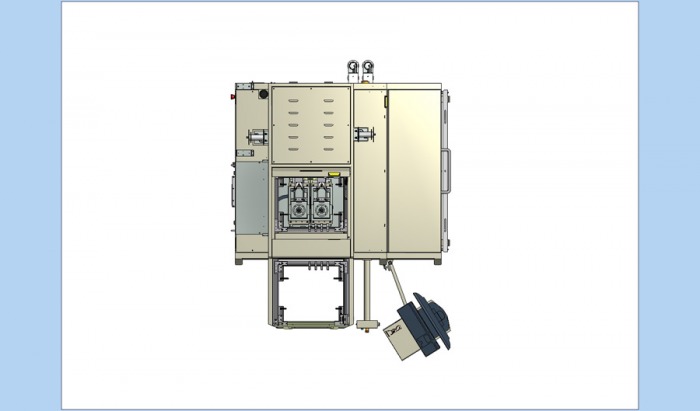

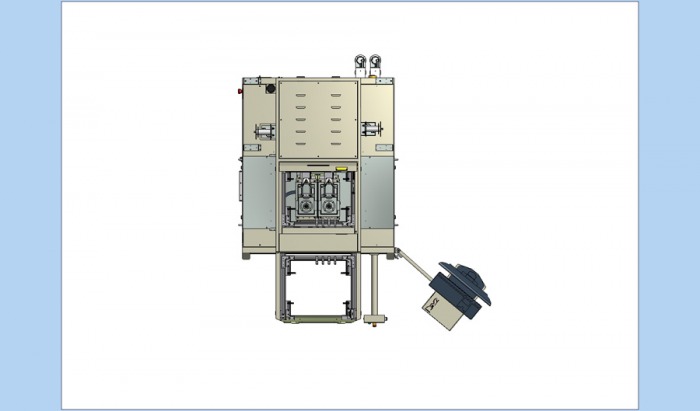

The Prodex is an offline system, incorporating a quick load twin PCB universally adjustable rotary table transport system to allow simultaneous load / unload during product processing.

Description

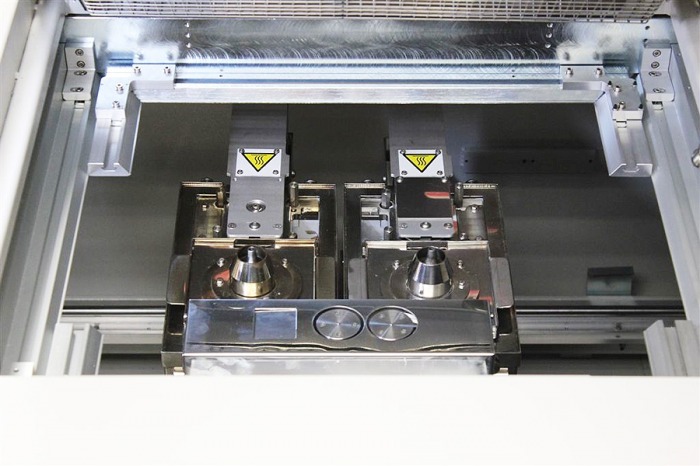

In its basic format, the Prodex is configured with a single solder bath. In its Duplex guise, the machine can be configured with twin adjacent solder baths on independent Z axis drives. This achieves increased production flexibility by permitting use of two different nozzle tip sizes which can be allocated as process requirements dictate within any particular area on a PCB.

All Prodex configurations can be offered with optional automatic heated solder bath change stations. Using this system the non-operational solder bath and pump system can be stationed at one of the two optional heated park positions located at either side of the main machine. This heated station, maintains the correct solder temperature within the bath that is idle so that when changeover occurs, the replacement bath can resume immediate production. A single automatic solder bath change station is identified as a PLUS configuration, whilst twin stations (located at both sides of the machine) are identified as PLUS PLUS configurations. On this basis Duplex machines with the PLUS PLUS identity will operate with 4 individual solder bath and pump systems.

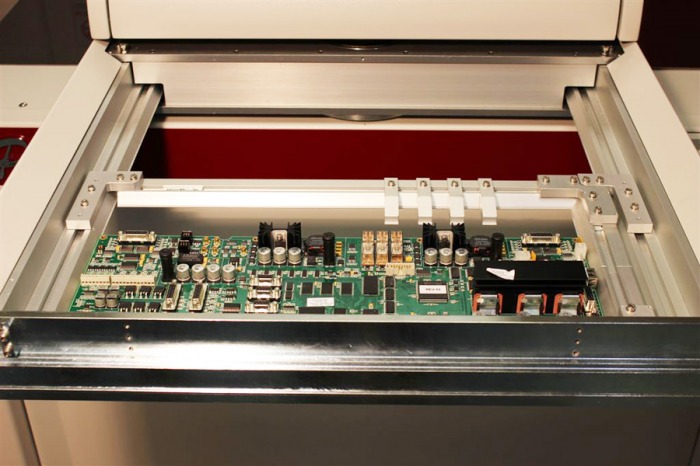

The Prodex series is controlled by a PC, through PillarCOMM, a Windows® based ‘Point & Click’ interface with a PCB image display.

Additionally our optional PillarPAD offline programming package allows the operator to produce programs independently from the machine using Gerber data.

Standard Features

- DC servo drives

- Rotary indexing table with twin adjustable positions

- Integral PC and machine mounted TFT monitor

- Inerted Nitrogen system

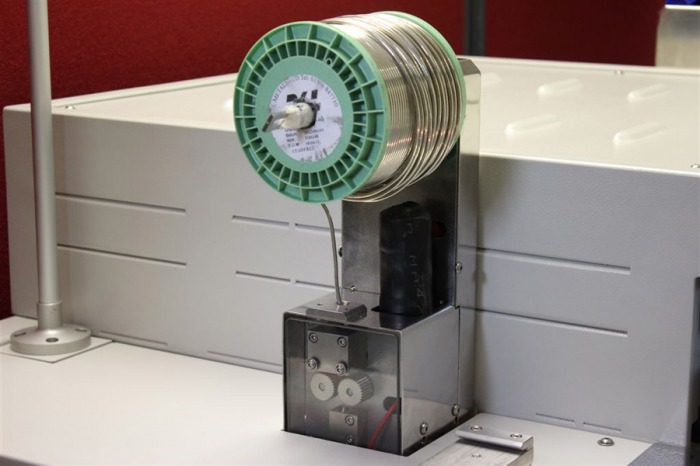

- Auto motorised wire solder feed & level detect

- Solder bath coding – identifies correct bath for program

- Drop-Jet fluxer

- Manual fiducial correction system

- Solder wave height measurement and correction

- Process viewing camera(s)

- Multilevel password protection

- Light stack

- Six AP style solder nozzle tips

- Internal fume extraction

- Colour programming camera

- PillarPAD offline programming system

- Universally adjustable tooling carrier

- Thermal nozzle calibration system using integrated setting camera – requires manual correction

- PillarCOMM Windows® based ‘Point & Click’ interface

- Lead-free compatible

- Day-to-day service kit

Monitoring Options

- Flux presence sensor – thermistor style

- Flux spray, flow and spray & flow

- Pump rpm

- O2 ppm

- Nitrogen flow

System Options

- Side mounted auto bath changeover – PLUS configuration

- Top-side instant IR preheat

- Bottom-side slide in / out instant IR preheat

- Closed loop pyrometer temperature control

- Bottom-side hot Nitrogen selective preheat

- Automatic fiducial correction

- Ultrasonic fluxing

- Dual Drop-Jet / ultrasonic fluxing

- Laser PCB warp correction

- Twin solder bath capability on independent Z axis

- Micro nozzle assembly

- Large solder bath for dedicated single dip applications

- Solder bath removal trolley

- Solder reel identification

- Larger PCB handling size

- Nitrogen generator

Specifications

- Height: 1208mm / 47.5” to 2025mm / 80”- with light stack

- Width: 1250mm / 49“ to 1460mm / 57”- with rotate

- Depth: 2020mm / 79.5”

2240mm /88” with flux bottles

- Board size: 457mm x 508mm / 18”x 20”

- Edge clearance: Above/below 3mm

- Height clearance: Above/below 40mm nominal

70mm max. top-side only

- Solder: Most commonly used solder types – including lead-free

- Solder pot capacity: 20kg standard – 30kg large bath

- Applicators: AP style – 2.5mm to 16mm dia.

Extended AP style – 2.5mm to 20mm dia.

Micro nozzle – 1.5mm to 2.5mm

Jet-Tip style – 6mm to 40mm dia.

Jet-Wave nozzle – up to 25mm width

Special dedicated nozzles available upon request

- Flux: Low maintenance Drop-Jet system. Low solids (below 8%), no clean flux, pressurised and inerted system, optional water soluble system available

- X, Y & Z Axis resolution: 0.1mm

- Repeatability: +/- 0.05mm

- Nitrogen usage: Up to 40 litres gas/min per bath using single bath with standard AP solder nozzle, 5 bar pressure.

Up to 80 litres gas/min using duplex twin bath configuration.

Refer to Pillarhouse for Nitrogen usage requirement with dedicated multi-tube nozzle assemblies.

- Nitrogen purity: 99.995% or better

- Power supplies: Three phase + neutral + PE

- Voltage: 230 V phase to neutral / 400V phase to phase

- Frequency: 50/60Hz

- Power : Maximum 9kVA per phase machine configuration dependent

- Transport: Hand load

- Tooling: Integral adjustable board guides, includes finger extensions and board clamps.

- Programming: PillarCOMM Windows® based ‘Point & Click’ interface

Gallery